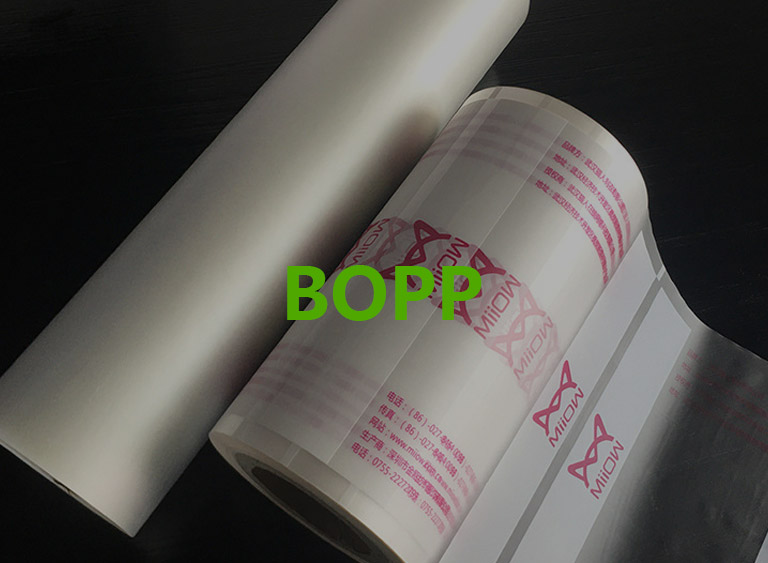

Biaxially Oriented Polypropylene (BOPP) film is a type of plastic film that is widely used for packaging, labeling, and lamination applications. In this post, we’ll provide an overview of BOPP film, including its features, applications, production, and recycling.

What is BOPP Film?

BOPP film is made from polypropylene, a thermoplastic polymer that is known for its strength, flexibility, and resistance to moisture and chemicals. BOPP film is produced by stretching polypropylene film in two directions, resulting in a material that is strong, lightweight, and durable. The stretching process aligns the molecules in the film, making it more resistant to tearing and punctures.

The Difference Between BOPP Film vs PP Film

While BOPP film is made from polypropylene, there is a difference between BOPP film and regular polypropylene film (PP film). PP film is a non-oriented film, meaning that it is not stretched in two directions like BOPP film. As a result, PP film is less strong and less resistant to tearing and punctures than BOPP film. PP film is typically used for applications where strength and durability are not as critical, such as garbage bags and disposable packaging.

Features of BOPP Film

BOPP film has several features that make it ideal for a wide range of applications. Some of the key features of BOPP film include:

- Transparency: BOPP film is transparent, making it ideal for applications where the contents of the package need to be visible.

- Moisture resistance: BOPP film is highly resistant to moisture, making it ideal for packaging products that need to be protected from moisture.

- Chemical resistance: BOPP film is highly resistant to chemicals, making it ideal for packaging products that contain chemicals or need to be protected from chemicals.

- Printable: BOPP film can be printed with a variety of inks, making it ideal for labeling and packaging applications.

Common Applications of BOPP Film

BOPP film is widely used in a variety of applications, including:

- Food packaging: BOPP film is used to package a wide range of food products, including snacks, candy, and baked goods.

- Labeling: BOPP film is used as a labeling material for a wide range of products, including bottles, cans, and boxes.

- Lamination: BOPP film is used in the lamination of paper and other materials, providing a protective layer and enhancing the appearance of the finished product.

- Adhesive tape: BOPP film is used as the backing material for adhesive tape.

Different Types of BOPP Film

BOPP film comes in several different types, each with its unique properties and applications. The most common types of BOPP film include:

- General BOPP Film: General BOPP film is the most widely used type of BOPP film. It is known for its high transparency, stiffness, and excellent printability, making it ideal for packaging applications such as bags, labels, and adhesive tape.

- BOPP Film with High-Shrinkage Type: BOPP film with high-shrinkage type is a specialty film that shrinks in all directions when exposed to heat. This makes it ideal for wrapping products with irregular shapes, such as bottles or cans. It is also used in the production of tamper-evident labels and sleeves.

- BOPP Heat Seal Film: BOPP heat seal film is a type of BOPP film that has a heat-sealable coating on one or both sides. This coating allows the film to be sealed to itself or other materials, making it ideal for applications such as snack food packaging, confectionery, and medical packaging.

In addition to these types, there are also several other specialty types of BOPP film, including matte finish BOPP film, metalized BOPP film, and anti-fog BOPP film.

Overall, the different types of BOPP film offer a range of properties and applications, making them a versatile and widely used packaging material. Whether it’s for general packaging purposes, high-shrinkage applications, or heat sealing, BOPP film is an excellent choice for a wide range of packaging needs.

What Machines Are Needed to Produce BOPP Film?

The production of BOPP film involves several steps, including extrusion, orientation, and winding. The machines needed to produce BOPP film include:

- Extruder: An extruder is used to melt the polypropylene resin and extrude it into a flat film.

- Tenter frame: A tenter frame is used to stretch the film in the machine direction and the transverse direction, aligning the molecules in the film and increasing its strength and durability.

- Winder: A winder is used to wind the film onto a roll.

Common Defects of BOPP Film

BOPP film can be subject to several defects, including:

- Wrinkles: Wrinkles can occur in the film during the extrusion or orientation process, leading to a reduced quality of the film.

- Gels: Gels are small particles or impurities in the film that can cause issues during printing or lamination.

- Fish eyes: Fish eyes are small circular defects that occur in the film due to impurities or contaminants in the resin.

- Holes: Holes in the film can occur due to issues during the extrusion or orientation process.

How to Detect Defects or Unqualified BOPP Film

To detect defects or unqualified BOPP film, manufacturers can perform various tests, including:

- Visual inspection: Visual inspection can help detect defects such as wrinkles, gels, fish eyes, or holes.

- Tensile strength testing: Tensile strength testing can help determine the strength of the film and detect any issues with the orientation process.

- Optical density testing: Optical density testing can help detect any issues with the transparency of the film.

- Coefficient of friction testing: Coefficient of friction testing can help determine the film’s ability to slide against other surfaces and detect any issues with the surface properties of the film.

How to Recycle Defected BOPP Film

BOPP film is recyclable, but the recycling process can be challenging due to the high level of orientation in the film. The orientation process makes it difficult to melt the film and recycle it into new products. However, there are several ways to recycle BOPP film, including:

- Mechanical recycling: Mechanical recycling involves shredding the BOPP film into small pieces and melting it down to create new products. While mechanical recycling can be challenging due to the high level of orientation in the film, it is still a viable option for recycling BOPP film.

- Chemical recycling: Chemical recycling involves breaking down the BOPP film into its chemical components and using them to create new products. Chemical recycling is a newer technology that is still being developed for BOPP film.

- Energy recovery: BOPP film can be burned as a fuel source in waste-to-energy facilities, which generate electricity or heat.

- New-tech plastic granulator: a new way to recycle defected BOPP film onsite, great for BOPP film manufacturers, no need to sell the scraps of defected BOPP film materials to the recycling center at a cheap price, you can easily recycle them onsite, right on the side of your BOPP film production line.

In conclusion, BOPP film is a versatile and widely used packaging material that has several key features, including transparency, moisture resistance, chemical resistance, and printability. While the production of BOPP film requires specific machinery, it can be subject to several defects, such as wrinkles, gels, fish eyes, or holes. To detect defects or unqualified BOPP film, manufacturers can perform various tests, including visual inspection, tensile strength testing, optical density testing, and coefficient of friction testing. While the recycling of BOPP film can be challenging, it is still possible through mechanical recycling, chemical recycling, or energy recovery.