Customer Profile:

In this case, the customer is a professional T-shirt Bag manufacturer. The company focused initially on the business of recycling blown plastic material, and capitalized on the growing polyethylene bag market with the purchase of 2 extruding and 2 sealing machines.

Problems manufacturer have:

“T-shirt bags will produce a lot of punching waste during the production process. Over time, more and more waste piled up in factories. Therefore, we have been looking for a solution to these accumulated wastes. Due to the relatively small factory area, a small machine is required. Also, environmental issues need to be considered..”

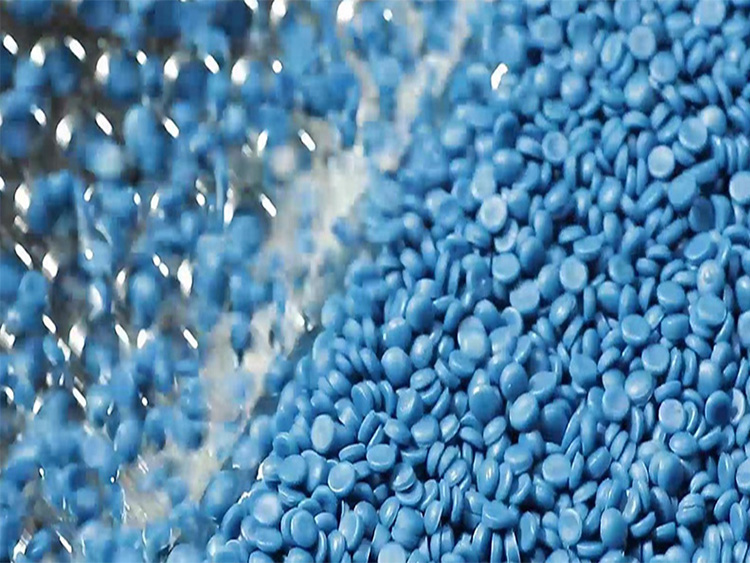

Our air-cooled plastic bag granulator help them:

According to customer inquiry, we recommened our HD-75 small plastic granulator, this machine is very easy to use and the occupy area is only 3 square meters, which is very space-saving. The output range is about 50 ~ 70 kg/hour, suitable for recycling the amount of T-shirt bag cuts-off they generated each month.