Understanding the Basics of Plastic Granulators

Plastic granulators are essential equipment for businesses that deal with plastic waste or scrap. They are used to break down plastic waste into smaller, uniform-sized particles for recycling or disposal. Choosing the right plastic granulator can be a daunting task, but with the right information, you can make an informed decision.

In this guide, we’ll cover the basics of plastic granulators, the different types of granulators available, and the factors to consider when choosing a plastic granulator.

What are Plastic Granulators?

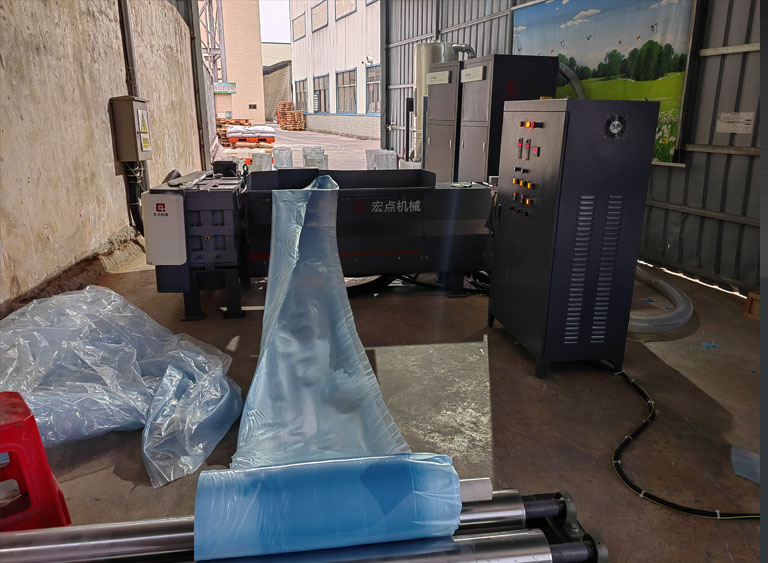

Plastic granulators are machines that are used to reduce plastic waste or scrap into smaller, uniform-sized particles. They come in different sizes and capacities, and are designed to handle different types of plastic waste.

The granulation process involves feeding plastic waste into the granulator, which then grinds and cuts the material using rotating blades. The resulting particles can be used for recycling, as feedstock for plastic manufacturing, or for disposal.

Types of Plastic Granulators

There are several types of plastic granulators available in the market, each designed for a specific purpose. Here are the most common types of plastic granulators:

- Central granulators – These are large, heavy-duty machines that are designed to handle large volumes of plastic waste. They are typically used in industrial settings, where high throughput is required.

- Low-speed granulators – These are smaller, low-speed machines that are designed to handle smaller volumes of plastic waste. They are ideal for businesses that generate small amounts of plastic waste.

- Shredder-granulators – These machines combine the functions of a shredder and a granulator. They are designed to shred plastic waste into smaller pieces before granulating them.

- Beside-the-press granulators – These machines are designed to be placed beside plastic injection molding machines. They are used to granulate the plastic waste generated during the manufacturing process.

Factors to Consider When Choosing a Plastic Granulator

Choosing the right plastic granulator depends on several factors. Here are some factors to consider when choosing a plastic granulator:

- Type of plastic waste – Different types of plastic waste require different types of granulators. For example, soft plastic waste may require a different type of granulator than hard plastic waste.

- Throughput capacity – The throughput capacity of a granulator determines how much plastic waste it can handle per hour. Choose a granulator with a capacity that matches your business needs.

- Size and space requirements – Plastic granulators come in different sizes, and you need to consider the available space in your facility before choosing a granulator.

- Maintenance and repair requirements – Plastic granulators require regular maintenance and occasional repairs. Choose a granulator that is easy to maintain and repair.

- Cost – The cost of a plastic granulator varies depending on the type and capacity. Choose a granulator that fits your budget, but also meets your business needs.

Conclusion

Choosing the right plastic granulator can be a daunting task, but with the right information, you can make an informed decision. Consider the type of plastic waste you generate, the throughput capacity you require, the available space in your facility, the maintenance and repair requirements, and the cost when choosing a plastic granulator.

With the right plastic granulator, you can efficiently and effectively handle plastic waste and contribute to a more sustainable future.